With these two measurements and our current M92 value for Y, we can now solve for our New M92 value.Ĭalculation for the Y-Axis and inputting data Now mark that point with a piece of tape and measure the true distance between those points (picture3). Place a piece of tape on the Y-axis over a point marked on the X-axis(picture 2). Next move your X-axis over until it lines up with the most outside part of your printer arm(picture1). The only real difference is finding another place to stick your tape to mark how far the Y-axis moves. This is pretty similar to what we've already done. When you get that done let's move onto the Y Axis. If so, you can return to the beginning of this step and double check that your X-axis is now calibrated. Type “M501” in your Gcode and scroll up in your log and make sure your new M92 for X has been saved.

3d printer rip rap pia i3 how to#

Now let's move on to the next step and learn how to input the New M92 value.įirst type in your G:code for your New M92 value like so : “M92 X79.22” then press enter (picture5) Then type In G:code: “M500” and press enter. This makes sense because our New M92 value is less than the Current M92 value(80.2), because we overshot our goal of moving the X-axis 70mm. 987724002 (New M92 value should be 98.77% of the Current M92 value) New M92 value = Desired movement / Actual movement * Current M92 valueħ0/70.87 =. Here's a formula you can use to solve for the New M92 value With these three variables we'll be solving for a 'New M92 value.' Then we need the two measurements we just took. First we need the 'Current M92 value' for X we made a note of in step one. We need 3 variables to calibrate our X-axis. Chances are you didn't get exactly 70mm on your first try though.

If you measure 70mm perfect, your X-axis is calibrated. Now use your digital calipers to measure what the "True measurement" is for the X-axis (picture 4) (picture 3) We'll call this measurement the "Desired movement." This is where your printer thinks 70mm is. Use another piece of tape at the same marker point you used before moving the X-axis. If you choose to move your X-axis further, you should have less margin for error, but you don't want to go too far and over shoot your printers capabilities. I like to start with 70mm (assuming you're using a 100x100x100mm printbed). In Repetier tell your printer to move its X-axis. Take a piece of tape (less flexible tape is preferred, so it doesn't sag) and place it on the printerbed parallel to another point of the printer that won't move when you move the X-axis.

Start by homing your X axis and raising the Z axis out of the way. A pencil and a pad of paper can come in handy too. This instructable assumes you got your printer running, it just needs fine tuning.

3d printer rip rap pia i3 software#

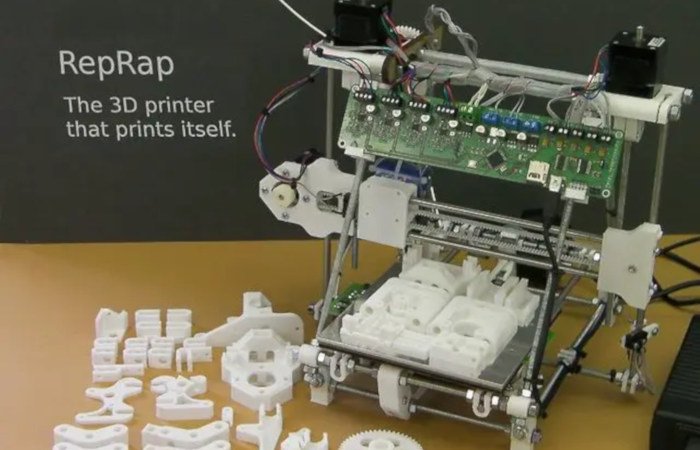

I'll be using a Printrbot simple and Repetier for this instructable, but you should be able to follow along with any printer and software combination. The following instructable shows you how to accurately calibrate your printer using minimal filament (filament is only needed to calibrate the motor that feeds the filament through the hotend). The good news is that once you know how to calibrate one motor of the printer, the rest are pretty well the same. One of the steepest learning curves when starting with 3D printing is learning how to calibrate all the motors accurately. So once you read through this one and understand the process, check out the follow-up HERE Instead of using tape to mark a location, a laser pointer can be used to achieve a higher precision calibration. I've made another Instuctable that builds off this one.

0 kommentar(er)

0 kommentar(er)